Epoxy resin dispensing machine

作者:點(diǎn)膠機(jī)???日期:2020-07-06 17:46???瀏覽:

Epoxy resin adhesive is a very mature glue, which has one-component and two-component types. Our company will manufacture appropriate dispensing device according to the type of use. The difference between single and double application effects is very big, because the two components need to be mixed in advance, control the flow of AB glue, and make it meet the requirements of mixing proportion. The single component is simpler, mainly focusing on the effect of glue coating and using epoxy tree Grease dispenser must understand the characteristics of glue and product production requirements. In order to better achieve the task of pouring glue.

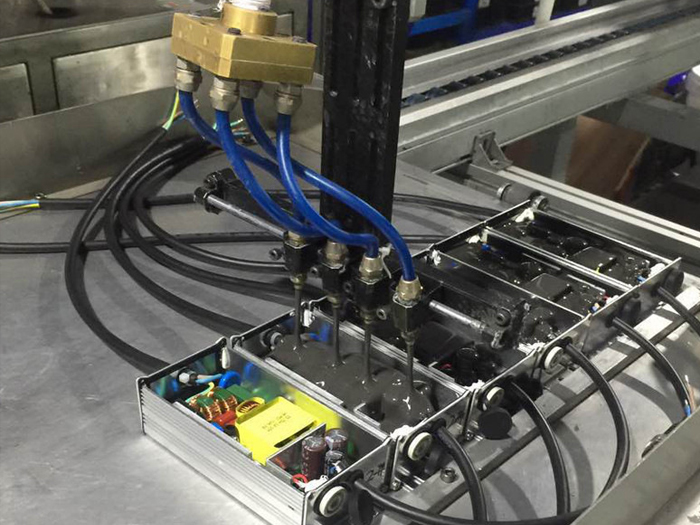

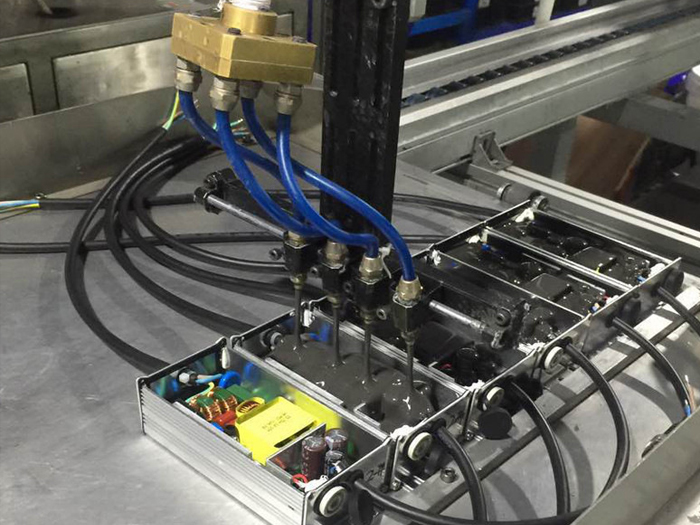

Application of epoxy resin dispensing machine

Electric toothbrush dispensing and magnetic core bonding will use one-component epoxy resin adhesive, while similar power supply, relay, capacitor, coil, ignition coil, etc., use two-component glue. Generally, the two-component glue will be more complex. The machine requirements are generally high-end, which is much more expensive than the single-component dispenser. However, the production effect is also very high, which can play the role of heating, defoaming, stirring, etc Mixing effect, and there are several dispensing shafts, which can directly realize glue pouring, but the operating viscosity is higher than that of one component epoxy resin dispensing machine.

The epoxy resin dispenser is also known as a dispenser, which is mainly composed of two liquids. It is convenient to distinguish the needs of manufacturers for machines. The use of single component dispenser can be called dispenser. The use of two-component dispenser can be called dispenser. Filling is mainly based on the flow rate, and rapid dispensing is its characteristics. According to its characteristics, the appropriate industrial application can be selected, such as dispensing mode in electric toothbrush or single component ring Oxygen resin dispensing machine as the core, in the circuit board or key gluing, pneumatic fixation and waterproof effect.

The use of epoxy resin dispenser can solve many problems of manufacturers, such as dispensing speed, pouring quality, constant glue, consistent quality, and various detection functions. It can quickly solve the problems arising from dispensing. There are not too many restrictions on the use of glue. As long as the viscosity meets the range, it can be used basically. For example, the viscosity of potting adhesive is similar to that of epoxy resin adhesive, and it is also single Component glue, of course, can also solve the problem of potting adhesive bonding. The glue used in magnetic core bonding is transparent potting adhesive, which is used for product bonding.

Parameters of epoxy resin dispensing machine

Model: zz-hy-s661 dispensing stroke: 500mm * 500 * 100mm (customized)

Machine size: 700mm * 590mm * 600mm (customizable) glue delivery mode: manual or automatic

Glue flow: 1 ~ 15g, glue head: single or multiple (customized)

Repeated dispensing accuracy: ± 0.02% dispensing accuracy: minimum line width 0.1mm

The minimum glue output is 0.1ml

Operating system: constant control system, PLC system of glue filling machine, driving device: synchronous belt + guide rail or screw + servo

Dispensing speed: 500mm / s product fixture: deliver a set of fixture

Power: 350W, power supply: AC220V

Characteristics of epoxy resin dispensing machine

1. Automatic procedures, can have good gluing effect, strengthen the core requirements of production

2. The production speed is fast, which can meet the production speed of six or seven workers.

3. Convenience, automatic program control, can quickly complete the gluing task.

4. Uniformity, the amount of glue poured into each product is the same.

5. Wide range, can meet a variety of glue and a variety of products gluing requirements.

Our company is specialized in the production of glue dispensing machines, dispensing machines, gluing machines, spray type and visual uniformity involved, has mature production technology, in order to meet the core needs of manufacturers, each machine is customized for manufacturers, the price is the same as the standard price, but it will have better use effect. Welcome to call the service hotline: 13662812001 (Mr. Wang, the same number as wechat)