5331 Three-Axis Dual-Position Automatic Dispenser

作者:馬交易???日期:2019-10-10 15:39???瀏覽:

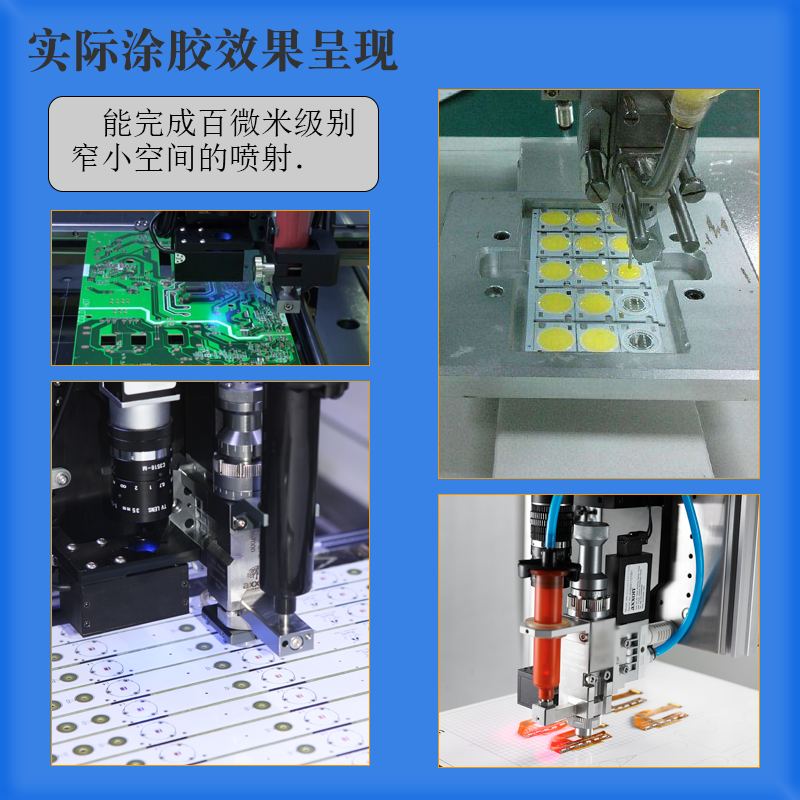

5331 refers to the dispensing distance and specifications of the automatic dispensing machine, the X-axis moving range is 500 mm, the Y-axis moving range is 300 mm, the Z-axis moving range is 100 mm, and the duplex position refers to two working platforms, which can realize placing products on one side, dispensing on the other side, taking and dispensing without delay. This is the characteristics of 5331 three-axis two-position automatic dispensing machine.

Dual-station automatic dispensing machine is a small and medium-sized machine with desktop structure. It occupies a small production area and can be used in dispensing at different work stations. It is flexible in production and can be applied to various products. Besides dispensing needle barrels, it can also be used with dispensing valves and glue pressure barrels. The production mode is also varied. It also adopts three-axis structure. Line, point, circle, arc and non-standard curve dispensing can be realized.

Production Advantage

Production speed and quality are definitely the most relevant topics for manufacturers. A 5331 three-axis double-position automatic dispensing machine can move at a speed of 500 mm/s, a dispensing valve can move at 450 mm/s, and the dispensing capacity can be adjusted at a width of 0.09~2 mm. With the help of needles, dispensing valves and air pressure, the dispensing speed can be adjusted. A double-position automatic dispensing machine is equal to three to four workers. The more complex the product is, the greater the difference in speed is. In addition, in terms of quality, the machine is faster than the manual.

Characteristics of automatic dispensing machine

1. Chinese handheld controller, Chinese display mode, fixed program, direct programming numerical value, easy to add simple.

2. It has the function of connecting points, lines, arcs, circles, concave and convex lines and irregular curves to realize 3D non-planar trajectory path gluing.

3. It has teaching function and supports various program access, such as array, graphics, three-dimensional ellipse, graphics insertion and group programming.

4. Super large storage capacity, programmed programs can be stored, supporting the storage of 1000 programs, programming once, no longer need to re-program.

5. Output speed, glue volume, glue type, out time, input pressure and stop time can be set by program.

6. With digital display controller, the rubber pressure can be designed regularly and the machine can be controlled. With this method, the rubber can be produced stably and conveniently, the rubber breaks clean, and the leakage is not easy to occur.

7. Optional non-curing glue device ensures that the glue will not dry when it is used the next day.

8. Use a large number of fluids: UV glue, hot melt glue, epoxy glue, two-component glue (1:1, 2:1, 4:1 and 10:1), instant dry glue, red glue, solder paste, anti solder paste, transparent paint and thread fixing agent, styrofoam, glass glue, etc. Generally, it conforms to the use of single component glue.

Machine parameters

Machine model: ZZ-5331 Machine name: Dual-station automatic dispensing machine

Maximum operating speed: 500mm/s repetitive accuracy: +0.01mm

Operating System Constant Control (Default)/Full-time Driving Mode: Runkang Motor + Synchronization Belt

Dispensing range 500*300*300*100mm Power supply and power: 220V 50~60Hz 350W

Machine Size: 780*720*600 mm Machine Weight: 65KG

Power Motor: Imported Stepping Motor (Japan) Maximum Load: X/Y 5KG Z 10KG

If you need or want to know the characteristics and price of 5331 three-axis double-position automatic dispensing machine, you can consult our manufacturer. The actual price also needs to be determined according to the requirements of the manufacturer. The pre-quotation can only give a rough price. If you need to call 139-2840-3389.