Important role attached to visual dispensing system

作者:馬交易???日期:2019-09-05 23:13???瀏覽:

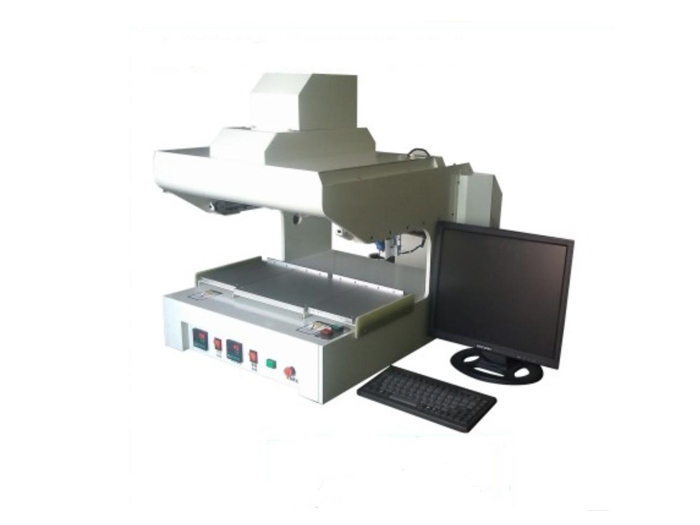

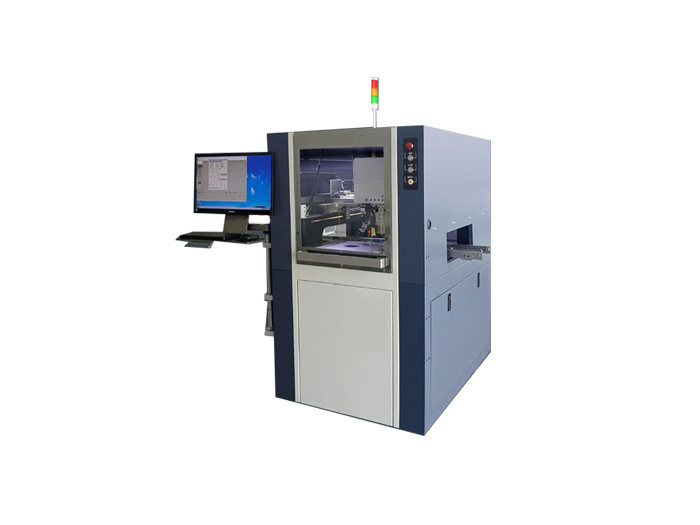

Visual dispensing equipment needs certain basic programming ability to complete the operation of the control system. It runs well and has relatively good performance. It runs steadily in the process of high-speed automatic dispensing of products and dispensing speed is very fast. The programming of general control system is controlled by the manufacturer to help users understand the operation of visual dispensing. System.

How to operate the visual positioning dispenser requires special learning by operators. After a period of understanding, operators will have a basic understanding of general operations and operations. In fact, the operation of the learning control system must first be familiar with the meaning of the key, so that the dispensing speed of dispenser can be adjusted more conveniently, and then the function and sequence of each step need to be understood in order to make the dispensing operation simpler.

Every step of the path programming of the operation control system is completed in sequence. It is not allowed to skip the operation or it will affect the quality and effect of dispensing. The programming steps of the operation of the visual dispensing machine should be carried out in sequence. First, after starting and entering the visual dispensing system, the scanner should scan the products that need dispensing or input, and then scan them. They are transmitted to the dispensing machine to obtain the identification keys of the control system, and then they are transmitted to the computer control system, so the visual dispensing system can be adjusted properly and put into normal use.

Combined with the above methods, the machine can operate and complete various high-speed dispensing operations skillfully. The dispensing effect is automatically adjusted by the control system, so there is no need for too much manual adjustment. In addition, the dispensing effect of visual dispensing system is much better than that of other dispensing equipment, but other types of dispensing equipment can not achieve this. Visual control system supports a variety of the same types of dispensing equipment, such as equipment used in surface coating and gluing machine, etc., through the establishment of visual dispensing system. Programming helps to enhance the surface coating effect of different types of products and meet the different production work of more users.

How to operate the visual positioning dispenser requires special learning by operators. After a period of understanding, operators will have a basic understanding of general operations and operations. In fact, the operation of the learning control system must first be familiar with the meaning of the key, so that the dispensing speed of dispenser can be adjusted more conveniently, and then the function and sequence of each step need to be understood in order to make the dispensing operation simpler.

How to operate the visual positioning dispenser requires special learning by operators. After a period of understanding, operators will have a basic understanding of general operations and operations. In fact, the operation of the learning control system must first be familiar with the meaning of the key, so that the dispensing speed of dispenser can be adjusted more conveniently, and then the function and sequence of each step need to be understood in order to make the dispensing operation simpler.