Application of automation equipment in automobile lamp dispe

作者:馬交易???日期:2018-08-14 11:31???瀏覽:

Now each industry has the basic automated dispensing machine production "figure", such as the automotive industry, lamp dispensing is the choice of two-component glue dispensing machine, using two-component glue, the most suitable use of two-component glue dispensing machine, so the effect of dispensing lamp is the best, of course, the glue dispensing machine also belongs to One of the automatic dispensing machines.

Why do you choose two component glue filling machine?

Why do two-component glue need to choose a two-component filling machine for dispensing, because two-component glue need to be stored separately, so need to use two pressure barrels, also need a two-component dispensing valve, so as to meet the current two-component glue bonding problem, the quality of car lamp glue can be guaranteed, the use of different. The glue needs a different way, for example: the use of silicone gel requires the use of silicone dispensing valve, and then with automatic dispensing machine to complete dispensing task.

Dispensing requirements for headlights

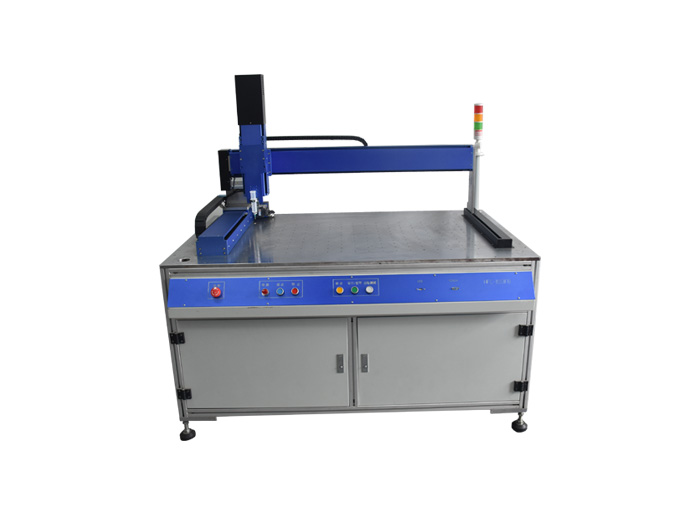

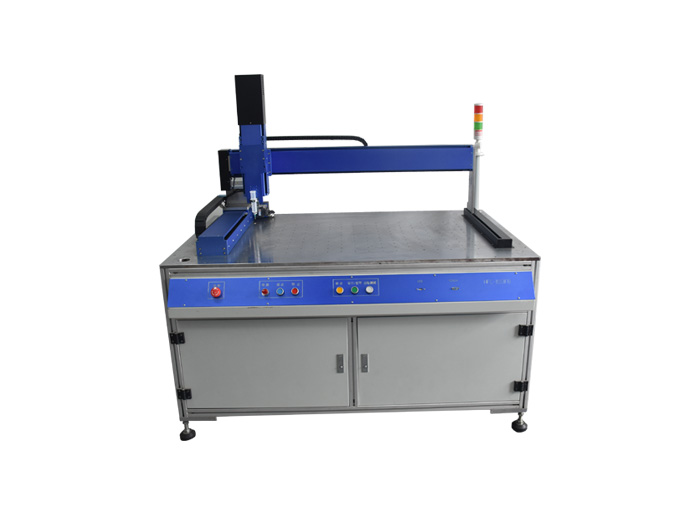

The requirement of glue dispensing is not high, but the requirement of glue is relatively high. First of all, glue should meet the requirement of waterproof, dustproof and high temperature resistance. In this way, when using automobiles, it will not cause water intake or other problems. This is also the reason why automobile lamps are packaged, so the requirement of glue is certain. For the two-component glue filling machine may be required according to the size of the lamp, the appropriate customization, the general standard automatic dispensing machine is not suitable for automotive parts dispensing requirements.

The size of the lamp and the shape of each lamp are different, so choosing the customized equipment can improve the dispensing flexibility. Just like using silicone gel dispensing, installing different valves can meet the dispensing needs of different industries, instead of using a rubber valve, it is certainly not able to meet a variety of dispensing requirements. Similarly, the use of two-component dispensing valve production, certainly to meet a variety of industries for dispensing, so that the purchase of automatic dispensing machine value can be reflected, will not lead to glue bonding problems.

Methods of reducing glue bonding problems

Glue bonding is easy to happen and hard to happen. Why? If the maintenance and maintenance of the two-component glue filling machine can be carried out, the probability of glue bonding problems is not high when dispensing the lamp, such as: double-liquid glue dispensing valve using silicone gel, the nature of the valve is not suitable for the use of silicone gel, which strong use will certainly lead to bonding problems, the lamp glue needs to be applied to fit. Suitable dispensing equipment, so as to meet the needs of production.