Automatic programming system of glue filling machine

作者:涂膠機(jī)???日期:2020-03-30 09:05???瀏覽:

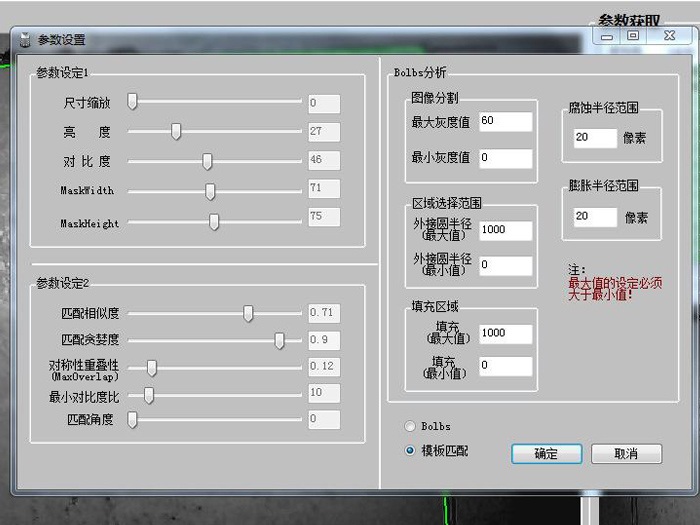

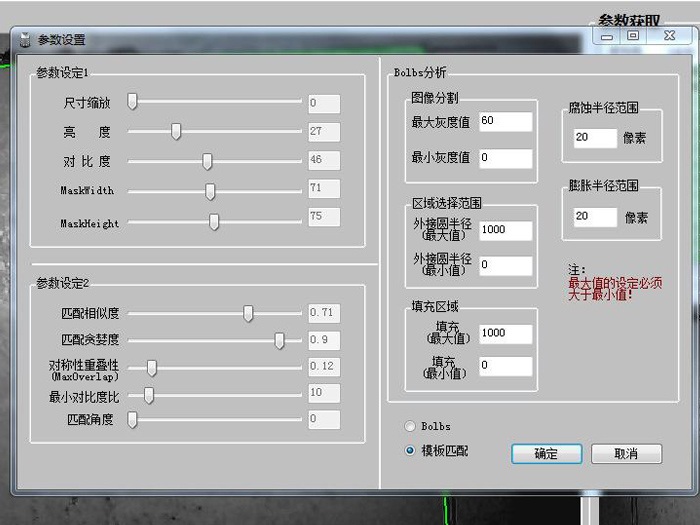

The automatic programming system is mainly used in the visual system. It can be set and input independently by relying on the computer and machine system. Under the control of the touch screen or handle, the input programming is also more convenient and easier to control. According to the requirements of the automobile lamp, it can realize automatic programming and control all aspects of the glue filling parameters, so as to complete the glue coating task ����。

For example, the auto lamp glue filling needs to be programmed. This is a standard two-component floor glue filling machine with no visual operation system, with PLC and touch screen. The program input or the handle programming mode is used. According to the auto lamp glue filling track, move the mechanical shaft, carry out product point-to-point, set the glue out time, stop glue time, advance, delay glue out and so on. All parameters can be set, The handle and the touch screen are synchronous, and can be saved for life as long as they are programmed once.

Automatic programming still needs manual assistance, otherwise it can't be realized. Although it can achieve automatic recognition, there is no manual operation, and there may be a little flaw in the details. Manual observation of track details makes it more accurate to point. Generally, automatic programming can be done manually only once, and this program can be used all the time later, which is very convenient. Double liquid landing irrigation The glue machine is applied to the car lamp glue filling machine, which is also a manual programming, or knowing all parameters, programming with computer, and then inputting the floor type glue filling machine in the form of file.

The hopper pressure bucket is used for the floor type glue filling machine, because the flow of glue filling for the automobile lamp is very large, dozens of kilograms of glue may be needed every day. The glue filling machine can complete hundreds of products in an hour, and adopt the double head glue out method to produce two products at the same time. The speed is certainly faster than that of the manual. At present, the technology of the two-component floor type glue filling machine is becoming more and more mature, with the function of adding glue halfway, which can be maintained every day Continue to fill glue, do not worry about glue used up, and also have automatic cleaning function, simple use, there are many functions to achieve.

Automatic programming is one of the functions of the floor glue filling machine produced by our company. If you want to know about the glue filling machine and funnel pressure barrel produced by our company, you can contact our company for business and answer the price and scheme questions for you.