There are two versions of filling valves, pneumatic and elec

作者:馬交易???日期:2019-08-29 15:46???瀏覽:

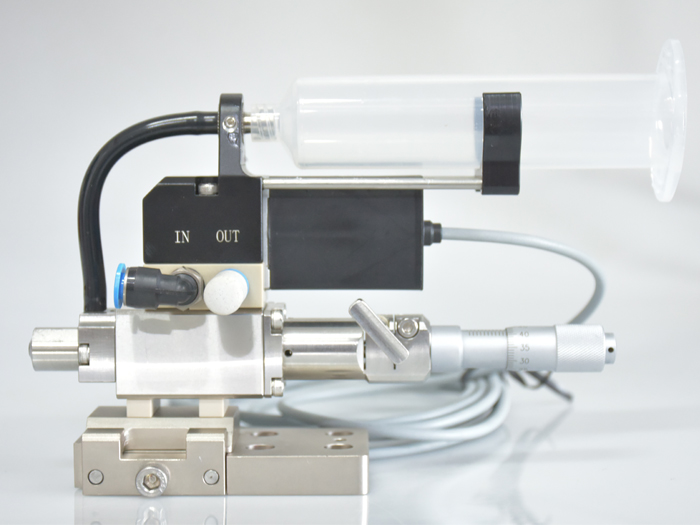

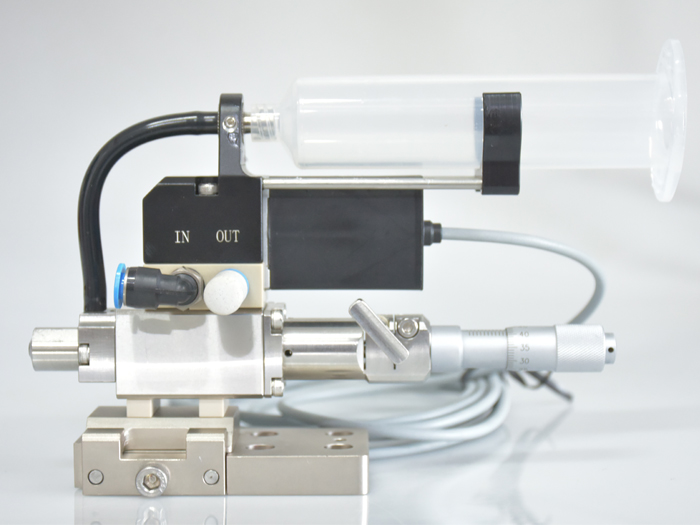

Pneumatic: The filling valve consists of three parts: cylinder, body and material cylinder. The cylinder and valve body are separated by stainless steel or segmented way to avoid glue contamination of the cylinder. The cylinder and material cylinder are connected with the main body of the filling valve. The pressure and the glue quantity can be gummed at the same time. The air pressure of solenoid valve drives the rubber valve center rod to move up and down, and through the center rod to move up and down, the glue is opened and closed.

The pneumatic glue valve can be divided into several types of rubber valves according to the bearing and the way of dispensing, which can be divided into plunger glue filling valve, thimble type glue filling valve, lifting glue filling valve and spray dispensing valve. Axis and dispensing methods are different, and suitable fluids are also different. For example, the backdraft dispensing valve adopts the closing structure of upward movement to stop the glue and absorb the glue instantaneously to achieve the glue collecting effect. The glue remaining on the needle will not leak or wire drawing. The filling valve is anodized by aluminium alloy. The sealing material is the latest tetrafluoro sealing ring and the rubber cylinder part is corrosion resistant material.

Electrical glue filling valve

Electrical: Including pump body, driving parts and integrated module, with motor device, simple installation. Working mode: Fixed rotor sealing structure is adopted, and the sealing performance is good. The self-sealing structure is formed by using the rotor and stator pairs and dispensing glue, which is easy to replace. The glue conveying function is realized by directional rotation of the stator with the rotor inside the rubber valve. Transportation process has no effect on the performance of the medium. At the same time, by reversing the motor, the function of the medium suction can be easily realized, and the cleaning of the medium and material can be ensured without dripping water and pollution.

Electrical: Including pump body, driving parts and integrated module, with motor device, simple installation. Working mode: Fixed rotor sealing structure is adopted, and the sealing performance is good. The self-sealing structure is formed by using the rotor and stator pairs and dispensing glue, which is easy to replace. The glue conveying function is realized by directional rotation of the stator with the rotor inside the rubber valve. Transportation process has no effect on the performance of the medium. At the same time, by reversing the motor, the function of the medium suction can be easily realized, and the cleaning of the medium and material can be ensured without dripping water and pollution.

Electrical: Including pump body, driving parts and integrated module, with motor device, simple installation. Working mode: Fixed rotor sealing structure is adopted, and the sealing performance is good. The self-sealing structure is formed by using the rotor and stator pairs and dispensing glue, which is easy to replace. The glue conveying function is realized by directional rotation of the stator with the rotor inside the rubber valve. Transportation process has no effect on the performance of the medium. At the same time, by reversing the motor, the function of the medium suction can be easily realized, and the cleaning of the medium and material can be ensured without dripping water and pollution.