How to choose automatic glue applicator for fireproof board

作者:點膠機???日期:2020-06-19 19:16???瀏覽:

The selection of automatic glue applicator for fireproof board mainly depends on three glue parameters: first, the product specification and size shall be given; second, the type of glue to be used and the glue parameters shall be given; third, the production speed requirements of the machine and the number of glue to be applied per minute shall be met. According to the basic parameters, we can decide which automatic glue applicator to choose.

First, product size

The automatic gluing machine has a gluing stroke. If the stroke is exceeded, the gluing cannot be carried out. For example, the gluing stroke of the fireproof board is 450mm and the width is 400mm. The machine needs a machine with a gluing stroke of 500mm. The fireproof board needs to be placed on the gluing working platform to carry out gluing. The product specification affects the size of the machine, and the small size cannot be glued.

Second, glue type

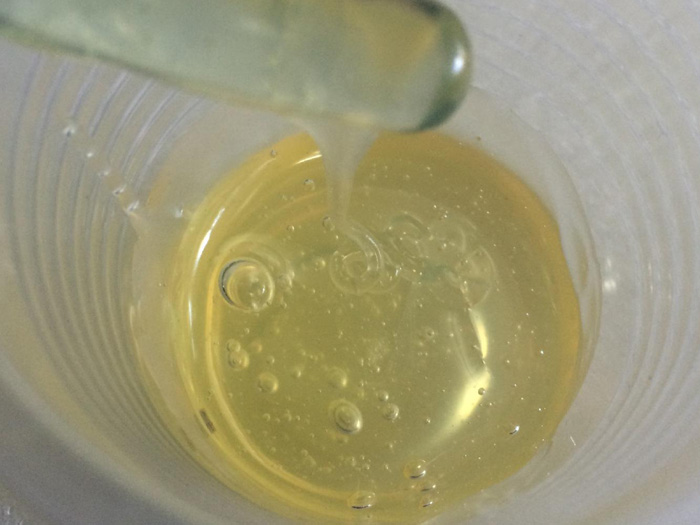

The type of glue mainly affects the rotation of dispensing accessories. For example, the glue viscosity is high, and the dispensing valve with low viscosity cannot be used. It is necessary to match the appropriate valve to avoid affecting the dispensing efficiency due to poor fluidity. It is recommended that our company's suction type gluing valve is a large flow valve, which meets the requirements of applying high viscosity glue and universal glue is in line with the requirements of furniture This valve is also used for gluing. It is also a suction type gluing valve in multi axis gluing machine, with a wide range of applications.

Third, speed requirements

There must be speed requirements in the production of fireproof board gluing, which can't meet the speed requirements. It's meaningless to buy a full-automatic gluing machine, or our company refits the machine for your company, which can't meet the requirements of using a full-automatic gluing machine. We can adopt a multi axis production mode, use a multi axis gluing machine, and produce three glues at the same time, so as to improve the gluing efficiency. If you can reach the standard, you can buy it. If you can't reach the standard, you don't want to buy it. If you can't return the machine and do business, you can be friends. Don't hurt the harmony, right.

This is the case in any product gluing. There are many applications of all-purpose glue gluing in fireproof board gluing and furniture gluing. Now the labor cost is too high. Machines can replace the shortage of labor. There are also rigid requirements for machine production, which can be produced for a long time every day without mistakes and meet the high strength requirements.

Gluing has gradually become the mainstream of production, of course, there are also manual steps that can not be replaced. Using machines can improve the production speed, especially for some products with requirements for dispensing accuracy, which can be produced by machines. Each line of the machine is drawn by three-axis positioning, without deviation, which solves the accuracy requirements of the products well, and can also be glued. This is how the fire-proof board gluing comes from Furniture gluing has some high technical requirements.