Analysis of the main factors affecting glue flow control

作者:馬交易???日期:2019-12-20 14:41???瀏覽:

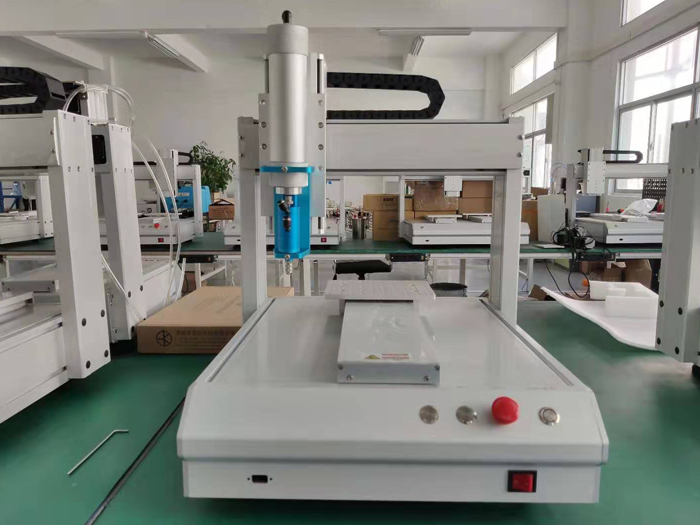

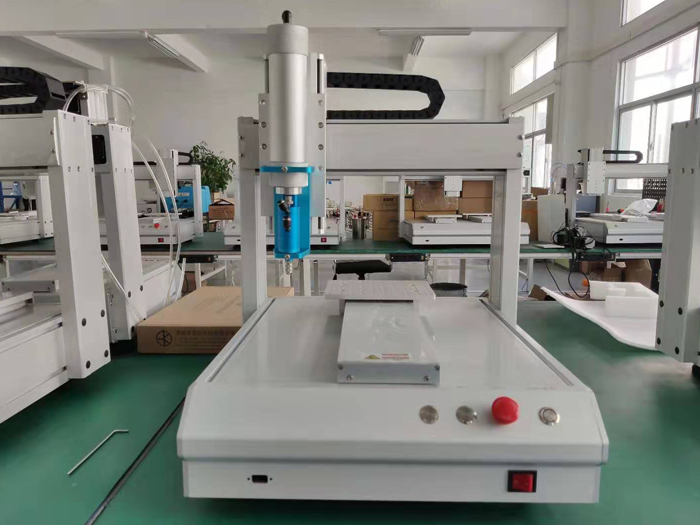

In the energy saving lamp dispensing flow control, there is a direct relationship with the automatic dispensing machine accessories. The accessories determine the dispensing amount, dispensing accuracy and glue control effect. The glue flow control must select the right accessories. The glue has a single component and a two-component component. The single component mainly depends on the viscosity, the two-component viscosity and the glue ratio. Analysis of the above glue characteristics can match the glue flow control configuration that meets the demand Pieces.

Single component glue is used for glue dispensing of energy saving lamp, with viscosity between 10000 and 30000. The viscosity is medium to high. The glue dispensing valve selects large flow rate and suction effect. The glue cylinder with large flow dispensing valve has a large area and independent cylinder. The single component glue with strong air pressure and high viscosity can still be used for glue dispensing. The glue flow control is stable. The suction effect is to improve the glue breaking effect and prevent glue from breaking There are drawing problems, such as high viscosity of glue, poor fluidity, no suction back. The use of energy-saving lamp dispensing is to use a large flow dispensing valve and achieve the combination of dispensing machine for product dispensing.

The two-component glue will be used for glue filling of inductance coil, with the glue ratio of 1:1 to 5:1. The two-liquid dispensing valve and metering pump are used for glue flow input calculation, and the two-liquid dispensing valve is used for mixing the two kinds of glue to carry out glue dispensing. There are also very complex steps, which need to be equipped with many accessories to achieve glue dispensing. The glue flow control is not simple. The inductance coil needs to be equipped with many accessories to achieve glue dispensing Glue filling is a simple two-component glue filling. For example, for ignition coil glue filling, large-scale automatic dispenser, vacuum defoamer and double liquid dispensing valve are needed.

Glue flow control is realized from the combination of accessories and machines. Energy saving lamp dispensing and inductor filling are different effects to achieve glue flow control. The characteristics of single component glue and double liquid component glue are different. If you want to know more about the effect of flow control, you can contact us!