What problems should we pay attention to when adding hot mel

作者:馬交易???日期:2019-08-27 17:25???瀏覽:

PUR hot melt adhesive is a kind of wet curing reactive polyurethane adhesive, which is widely used in paper, bottle cap, computer, mobile phone and other high-end applications. TP of flexible surface mobile phone combines with intermediate frame. It has excellent bonding performance, but it needs to be heated by hot melt glue before dispensing. This is a special type of glue.

PUR hot melt adhesive has many advantages, such as good viscosity, high adhesion, fast curing speed, waterproof after curing, high temperature resistance and no environmental impact. However, the failure of hot melt adhesives may occur because the hot melt adhesives can not be heated or other problems in the operation process, which may affect the production efficiency. Generally, these reasons lead to failure:

1. Insufficient heating temperature and hot pressing time of hot melt adhesives

Hot melt adhesives have their standard melting temperature, so glue type should be selected according to the characteristics of dispensing products. If the temperature is too high or too low, it is easy to cause different problems of hot melt adhesives. For example, the temperature is too high, resulting in the reduction of the amount of adhesives, resulting in the inability to adhere to the product surface. Low temperature will make hot melt adhesive unable to melt or incomplete melting.

Secondly, select (or design) inappropriate types of hot melt dispensing valve joints.

It may be that the length of overlap is too long, the linear expansion coefficient of different materials is not taken into account, the stiffness of the adhesives is not enough, and the uneven tension is seriously affected. The strength of the bonding material and the unsealed wrap angle at the end are affected by the peeling force, and the laminated material overlaps and the part under stress is inclined.

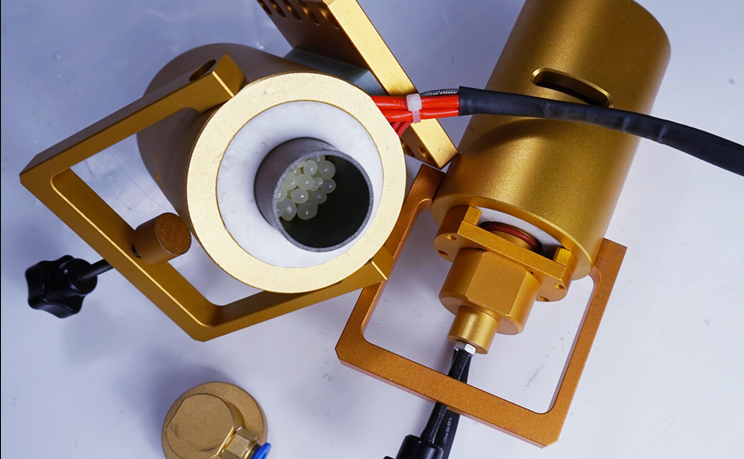

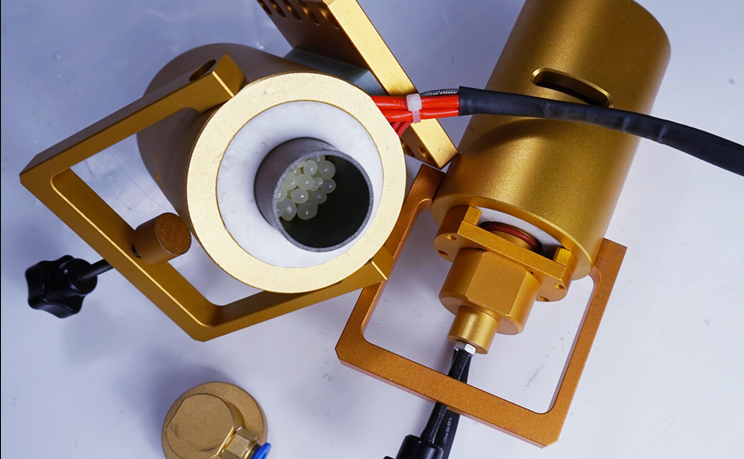

3. Improper use of hot melt dispenser

On the hot melt dispenser, the hot melt adhesive is heated by pressing and heating through the heat conducting copper mould. If the copper die is not balanced with the product, the edge is high, the edge is low, and the heating of the parts is uneven. Therefore, it is necessary to adjust the verticality between the copper die and the product.

IV. Improper Bonding Technology

For example, when the surface of adhesives is treated, the amount of hot melt adhesives is too much or too little, or when the adhesives are unstable, the bonding time, such as some need to be bonded after a period of time, some things need to be adhered to in time and other reasons.

1. Insufficient heating temperature and hot pressing time of hot melt adhesives

1. Insufficient heating temperature and hot pressing time of hot melt adhesives Secondly, select (or design) inappropriate types of hot melt dispensing valve joints.

Secondly, select (or design) inappropriate types of hot melt dispensing valve joints. IV. Improper Bonding Technology

IV. Improper Bonding Technology